Software Used on this Project

Project Overview

For a major linear infrastructure project in the United Kingdom, Arup utilised cloud geotechnical analysis software Oasys Gofer to model a section of a cantilever embedded diaphragm wall. They compared its performance against previous analyses conducted using Oasys Frew and other Finite Element Analysis (FEA) tools in the market. Our next generation 2D FEA geotechnical analysis tool, Gofer, brings the power of cloud computing to geotechnical engineering. The primary objective of this project was to assess the feasibility and effectiveness of using Gofer as an alternative for these traditional analysis tools.

How Oasys proved invaluable

Modelling

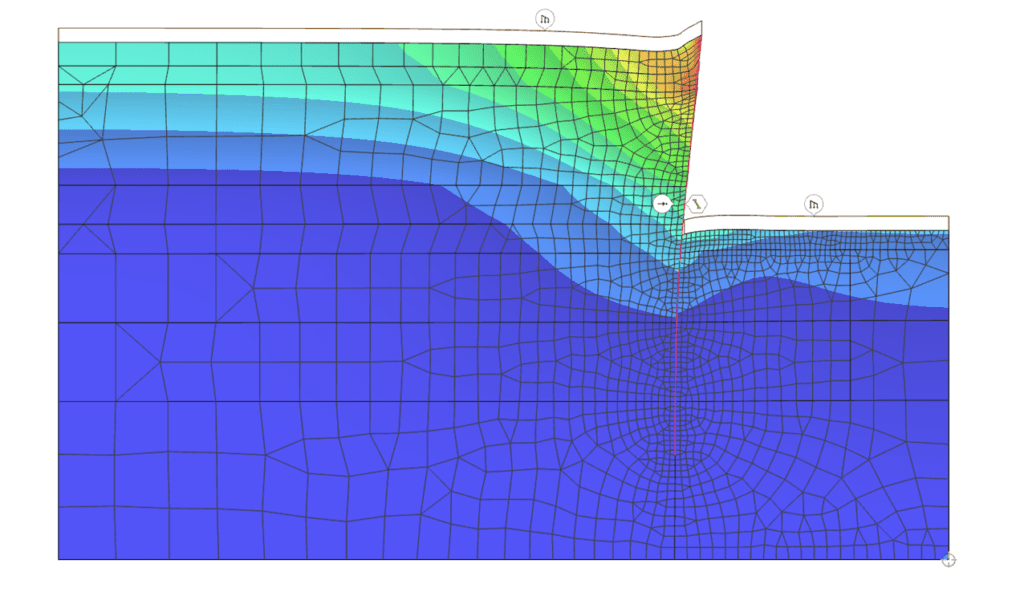

The engineers found that creating the model geometry was streamlined and user friendly. Defining soil blocks and material properties was intuitive, allowing them to specify all necessary general and mechanical material parameters required for accurate analysis and comparison of results.

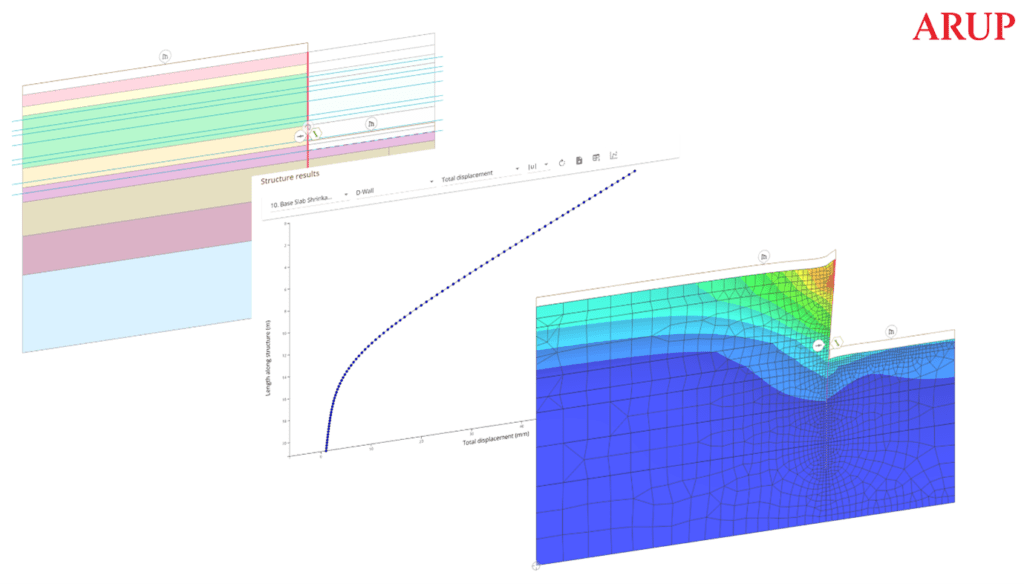

The diaphragm wall was modelled as a structural element, and engineers noted that the structural components were easy to draw and define using the lightweight parameter input interface. Initially, the base slab was modelled as a prop, similar to the strut approach used in Frew. Additional checks involved modelling the base slab as a full structure at haunch soffit level, which yielded very similar results to the strut approach.

During the model geometry phase, engineers identified a minor discrepancy between the defined vertical rigid boundaries and the generated soil block node positions, which allowed soil to displace into the void between the block and rigid boundary. After discussing this issue with the Oasys team, they were able to inspect the coordinates of the vertical nodes along the edge of soil blocks, allowing them to identify and address the discrepancy.

Overall, engineers found that drawing model geometry and defining and assigning materials in Gofer was less complex compared to other FEA analysis tools.

Analysis

The engineers found that defining stages in Gofer is straightforward and user-friendly. The ability to reset displacements and adjust numerical convergence controls enabled them to fine-tune more complex stages that required greater processing power.

A particularly appreciated feature was the ability to view results immediately after each stage was analysed, even while the analysis of later stages was still ongoing. This allowed the engineers to abort analyses if problems were identified early in the sequence, preventing potential issues that might not necessarily result in analysis failure.

Results

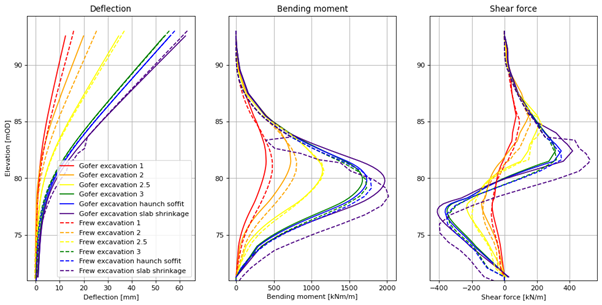

The results highlighted a close match between Frew and Gofer displacements, particularly during the later stages of excavation. Results of wall displacement, moments and shear force are presented below:

The restraint from the base slab, long-term dewatering, and base slab shrinkage effects were effectively modelled by applying uplift moments to the slab and shrinkage force point loads respectively. The results exhibited expected behaviours from these effects, with wall deflections—and thus bending moments and shear forces—subtly increasing from their previous fixed position post base-slab installation. The method adopted in Frew was slightly different, resulting in small differences in bending moment and shear force profile in the shrinkage stage.

Summary

Overall, Gofer showed encouraging results, matching Frew well, especially during later excavation sequences. Constructing the model was straightforward for the engineers, and with the knowledge of how to incorporate more complex long-term effects and troubleshooting techniques, long stage construction (10+ stages) with short- and long-term geotechnical and structural effects can be modelled with confidence.

We’d like to thank Engineer Mike Morrison at Arup for sharing this work with us.

Like what you see? Register your interest today to talk to our team about getting started with Oasys Gofer. Head to the product page to learn more about our cloud-native 2D FEA solution for everyday geotechnical analysis.

Join us on the journey to cloud!