Software Used on this Project

Project Overview

This 300 seat grandstand is located in the Valley of Chevreuse, a suburban countryside region in the south of Paris.

The structure is founded on 24 piles, each 14m long. The substructure and slabs are made of prefabricated concrete elements assembled on site. As the construction is embedded in the hill, this concrete structure is surrounded by retaining walls.

The Canopy is a 3D steel structure covered with transparent and green polycarbonate scales.

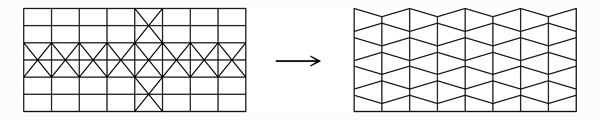

On the left side: Conventional structural diagram of an industrial steel structure

On the right side: The structural bracing diagram of the Chevreuse Grandstand Canopy

The main singularity of the project lies within the geometrical arrangements of the steel structure secondary beams, which are used to brace the whole structure without casting connections.

How Oasys proved invaluable

General:

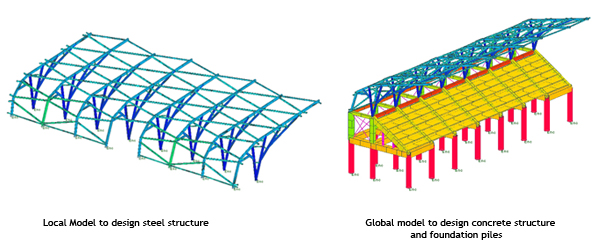

As the principle of the 3D steel structure is not conventional, GSA was found to be a very useful tool to confirm hand calculations and to conduct a global check that every structural member followed the requirements of the Eurocode Design Code. All calculations were made using GSA. Local and global models were used to complete the calculation.

Geometry:

The wireframe geometry of the structure was made using Rhino and then imported into GSA using the .dxf/.dwg import feature of the software.

Structural settings:

The following features of GSA were used to set up the calculation models:

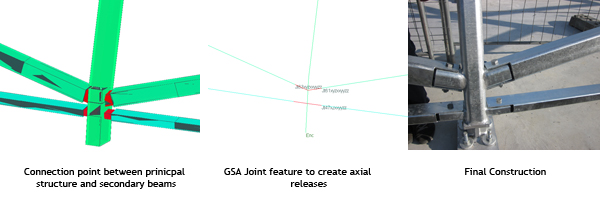

- Rotational release (basically yy and/or zz releases) are input through the “modify element” menu

- Translational releases in the local axes of certain beams had to be input in the steel structure to properly model sliding connections between these elements using joints (translational element releases were not available at the time). To proceed, the joint feature of GSA was applied by:

- Creating a new node with the same coordinates as the point where the translation release has to be created

- Exchanging the common ending node of one of both elements with the node previously created

- Linking the new node to the other (which have exactly the same coordinates) through the “constraint -> joints” menu and let the movement free between both nodes either in the x, y or z direction of the global coordinate system.

- As the bracing system of the structure is unconventional and the connection system between steel elements is unusual, joints allow the realistic modelling of the physical connections between all elements and give accurate calculation under thermal loads.

Loading:

The steel structure as well as the concrete structure and the foundation are calculated using the Eurocode Design Code. The structure was checked under 20 basic load cases such as:

- Dead load

- Live loads

- Snow loads

- Wind loads

- Thermal loads

- Support settlements

- Due to the compatibility between Excel and GSA, a combination of loads based on Eurocode Design rules were created with a routine program on Excel 2010 and then easily copied into GSA

- Combination cases envelopes were then put through “Cases and Tasks -> Analysis Tasks Menu -> Analysis Envelope” according to which part of the structure and under which state of loads it must be checked (ELS rare or ELU for the steel or the concrete parts of the structure, Structure global static equilibrium, reactions on piles, etc)

- The envelope of results obtained with GSA for element displacements, forces and bending moments, reactions at nodes, etc. were directly used to design elements as well as connections and concrete elements reinforcements

- A total of 1597 linear combinations within 4 envelopes analysis tasks were assessed using GSA

3- Credits

Client:

- City of Chevreuse, Yvelines

- Budget : €440 000

Design team:

- GMGB : foundations, concrete and steel structural engineering,

- SCP Beguin & Macchini: Architects

Building team:

- SPIE Fondations: piles / foundations

- TMB + Gilva: prefabricated concrete structure and retaining walls

- Ateliers Bois: Steel Structure,

- EIF: Polycarbonate Roofing Scales