Software Used on this Project

Project Overview

King’s Cross station is London’s busiest transport hub. Arup played a huge part in the redevelopment of the mainline station in collaboration with architect John McAslan + Partners (JMP), which has shaped London’s transport as we know it today. Part of the redevelopment involved designing the now iconic roof structure, whereby both Arup and JMP worked together to master the structural challenges. Oasys GSA was the structural analysis software of choice for the analysis and design of the Western Concourse roof.

© Hufton+Crow

How Oasys proved invaluable

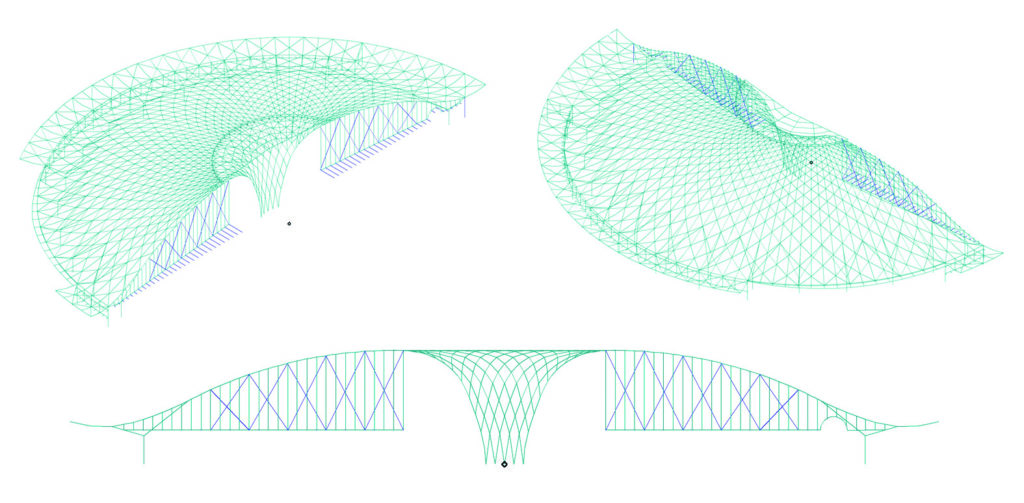

Arup used Oasys GSA with a parametric design approach to develop and finalise the entire roof diagrid and funnel. The engineers faced several structural challenges during this project. One of which being that the London Underground northern ticket hall box was already under construction at the time the roof was being designed. The engineers had to overcome the tricky long span of the structure and the way it would completely bridge over the London Underground. It was imperative that the structural scheme was efficient as well as elegant, did not apply any loads to the Western Range façade, and that it would fit within the curve of the Great Northern Hotel. The structure also had to be welcoming, visually appealing and operationally unifying as it would form a hub to connect the suburban and mainline intercity platforms.

© Arup

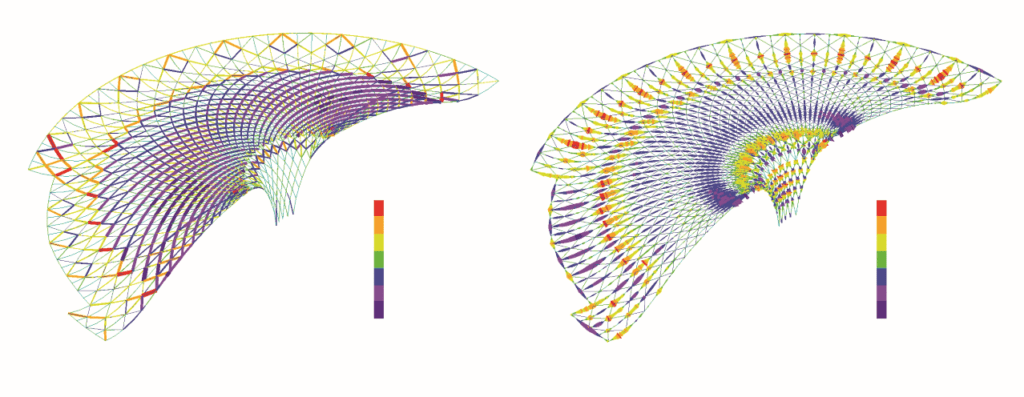

The ‘tree trunk’ columns at the base of the funnel needed to resist large net lateral thrusts from brand struts which would support the roof. These formed a shell shape in the roof diagrid. The radial forces at the top of the columns are up to 600 tonnes and produce a considerable amount of bending moments in the column itself, as well as large overturning loads at the baseplate. However, the restraint forces in the minor axis are only 90 tonnes in the horizontal direction. The branches are pin ended at the connection to the diagrid shell which allows the roof to articulate and avoid bending forces being transferred from the diagrid radial members into the branches themselves.

© Arup

As mentioned above, the long span of the structure presented several structural challenges for Arup engineers. A core part of the structural analysis involved checking in GSA for global and local buckling of the elements under the extremely high loads.

© Andy Gardner/Arup

The largest, most visible part of the concourse roof structure are the connections (nodes) between the tree column branches and trunk which had to transfer significant forces from several directions down to the foundations. Following a GSA analysis, it was decided that a solid cast ‘node’ would be the best solution. A 3D finite element model of each node was analysed to optimise the plate thickness and geometry within the constraints of the casting process. Through detailed design of the roof and close collaboration with the architect, no bolts are visible when standing in the station as all the connections are hidden within the structural members themselves.

© Hufton+Crow

The use of GSA allowed Arup engineers and JMP to carefully group the connection types which gave some uniformity to the connection design whilst still achieving an efficient and lightweight roof. Overall, GSA analysis and design capabilities produced a clean structure that has no interruptions to the curving geometry of the diagrid.

We’d like to thank Arup for sharing this work with us. Read more about the project on the Arup website or check out the Arup Journal detailing more about this fantastic project.