Software Used on this Project

Project Overview

The Maari oil fields are located some 100 kilometres off the west coast of New Zealand’s North Island in the Taranaki basin. Arup were brought in to provide detailed design of the platform substructure, including structural design of the base, jacket and deck, foundation engineering, naval architecture, outfitting design and installation systems design.

The platform substructure is based on Arup’s DrillACE concept successfully implemented in 2004 for the Yolla platform, Bass Strait, Australia, but with increased capacity for the deeper water and harsher conditions offshore New Zealand. The Maari Well Head Platform will yield approximately 35,000 barrels of crude oil a day.

How Oasys proved invaluable

Design of the Wellhead Platform

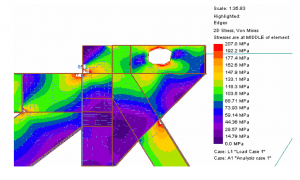

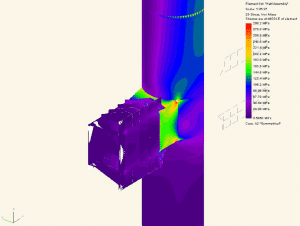

GSA was used to model the plated base, deck structures and model of the platform jacket structure. The plated structure was analysed in GSA for loadout, lifting and installation conditions, and GSA was also used to analyse a number of refined local models.

The base and deck structures for Maari were fabricated from stiffened panels, which were modelled in GSA using eight noded quad elements for the plate, and offset beam elements for the stiffeners.

The model of the jacket structure was created in GSA and exported to the ASAS offshore design package, where wave loads were applied to the model, and code checking carried out. The data transfer between the programs was automated using the GSA COM interface.

GSA was used for the plated structure analysis as it provided an easy to use pre- and post-processor. The ability to work with other design tools further enhanced the utility of GSA.