Software Used on this Project

Project Overview

Coire Glas is a pumped storage hydro scheme currently being developed by SSE Renewables in the Great Glen in the Scottish Highlands. A recent phase of exploratory works included a 1.2km long and 4.5m diameter exploratory adit completed by Strabag between December 2022 and August 2024. Completion of the adit produced over 60,000m3 of material, which if disposed of offsite would have had negative environmental and cost impacts on the project. Strabag appointed Arup to design a Spoil Storage Area (SSA) on the steeply sloping banks of Loch Lochy which would be capable of storing all material recovered from the adit and stored in such a way it had the potential to be repurposed during the Main Works. This appointment included identifying key site constraints, scoping of a ground investigation and subsequently deriving in-situ material parameters. These steps helped achieve the main objectives, which were to design sufficient storage platforms for separately graded spoil recovered from the exploratory adit and to iteratively optimise platform slope design to minimise material import and handling.

Arup completed a detailed slope stability analysis using Oasys Slope to design the spoil storage area on Loch Lochy’s steep banks, 1.5 km from the exploratory adit along the Great Glen Way which was used as a haul road for the duration of the works. The final size of the spoil storage area measured 250m by 100m, capable of storing up to 90,000m³ of spoil, which is intended to be reused in the Coire Glas main works.

Cleared spoil storage area pre platforming works (Dec 2022)

The key site constraints, identified through the completion of a Geotechnical and Geo-environmental Desk Study included shallow groundwater, debris floods, the stability of existing and constructed slopes, interface with the public and flooding and ecological constraints such as protection of Loch Lochy.

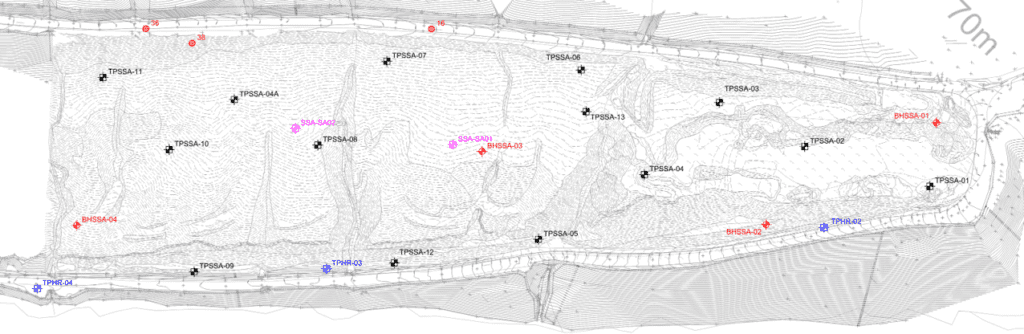

Spoil storage area ground investigation location plan

The ground investigation at the location of the spoil storage area was conducted by Natural Power in December 2022. The scope included four boreholes, thirteen trial pits, in-situ testing (SPTs and Soakaways) and laboratory testing. This analysis informed the development of the spoil storage area arrangement.

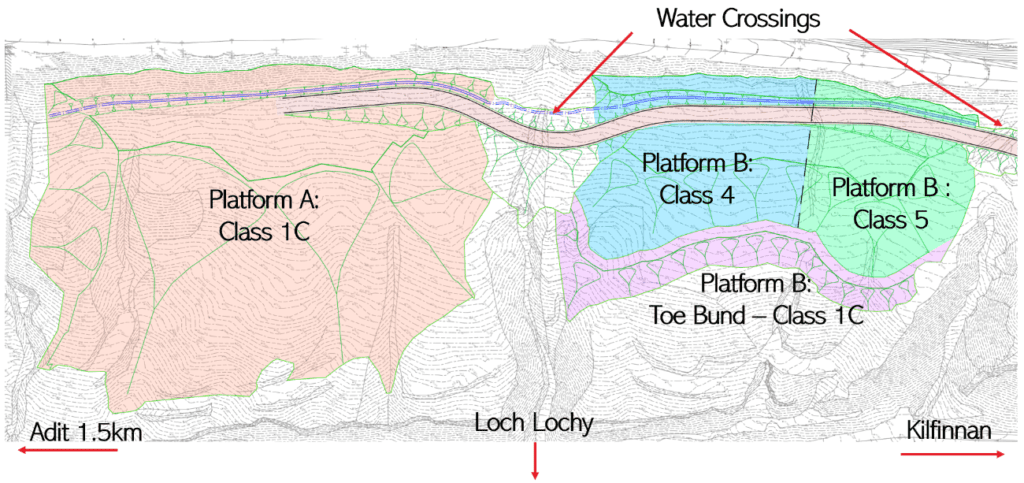

General arrangement of spoil storage area at detailed design

How Oasys proved invaluable

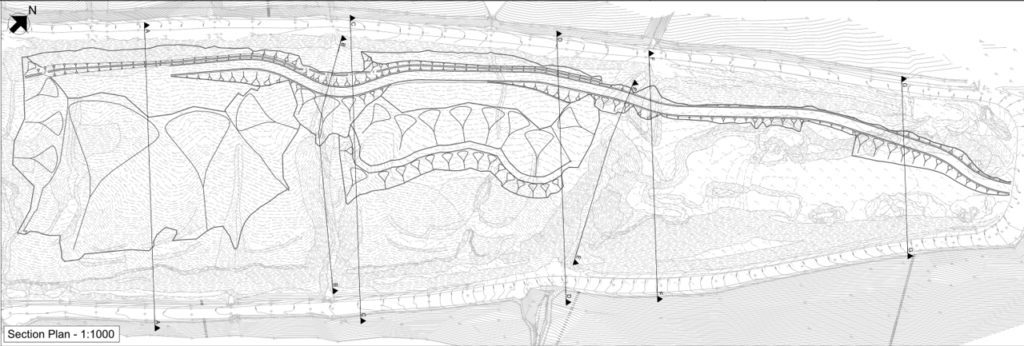

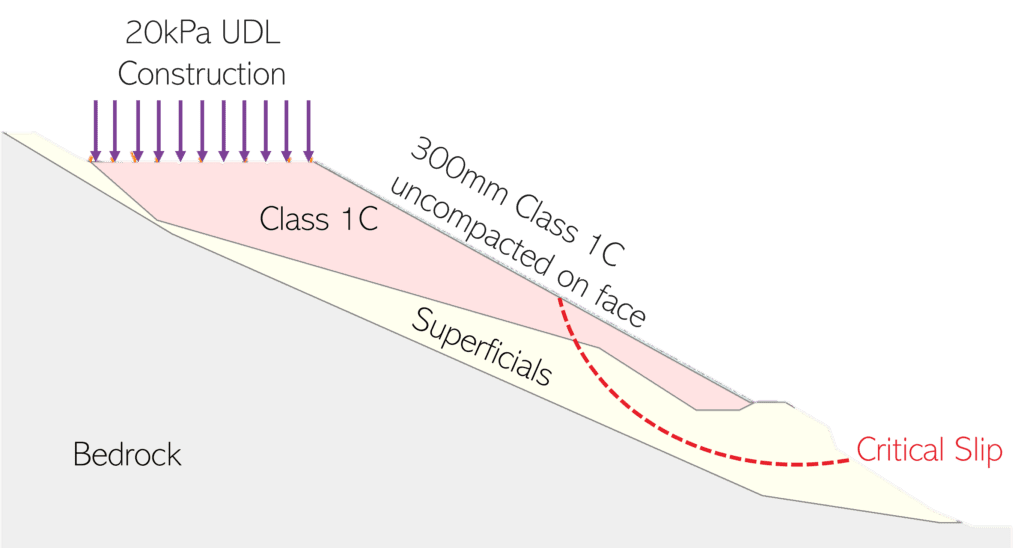

A detailed slope stability analysis was conducted using Slope which considered the derivation of in-situ material parameters from the ground investigation and conservative but reasonable assumptions to the adit material. The placement and method of compaction were also considered. The key assumptions were that there would be 20kPa UDL construction traffic at the crest, groundwater at 0.45mbgl and drained conditions. Seven critical sections were analysed to determine suitable slope design angles.

Critical sections chosen for detailed design analysis to assess stability of the SSA

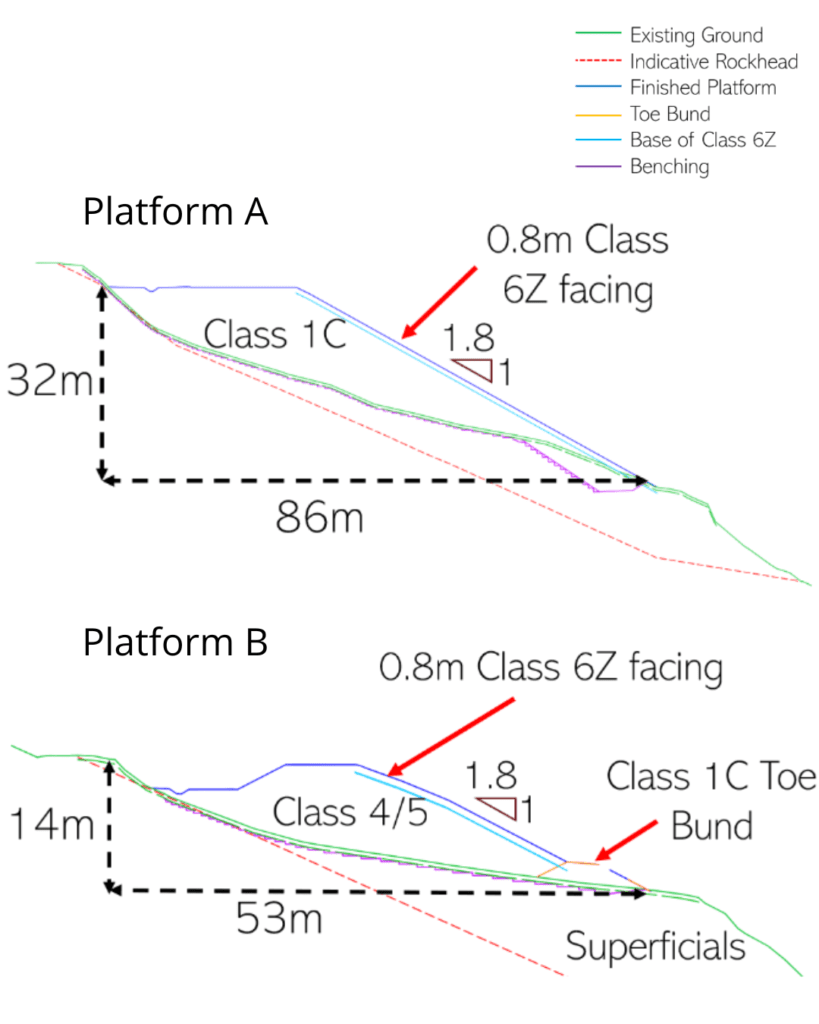

Design Platform A (Class 1C) and Platform B (Class 4/5)

Arup visited the site in June 2023 upon commencement of the exploratory adit to visually assess the ‘as blasted’ adit material. Key observations included; the adit material contained minimal fines, was well graded and subangular to angular. However, there was a low quantity of larger particle material suitable for the Class 6Z material design requirements (150 – 500mm). This visit resulted in a design adaptation which included an improved Class 1C friction angle which allowed for removal of all Class 6Z material without increasing the footprint of the SSA or altering slope geometry. Importantly, this meant there was no need for imported materials to comply with the design, reduced material management and no material requiring disposal offsite.

Revised Platform A design

Summary and learnings

The SSA was successfully completed in Autumn 2024 without unnecessary delays despite multiple challenges. Using Slope, Arup efficiently designed spoil storage platforms for different gradings, eliminating the need for significant redesign by making conservative initial assumptions. Continued designer involvement during site development resulted in no spoil material being exported off-site for disposal and no material was required to be imported to achieve slope stability.

We’d like to thank Sarah McKee, Geotechnical Engineer at Arup, for sharing this work with us.

Learn more about Oasys Slope.