Software Used on this Project

Project Overview

The Smithfield Poultry Market roof project, which won the award for exceptional analytical work at the Structural Awards 2024, highlights the vital role structural engineers play in revitalising existing structures. Originally designed in the 1960s, the roof is a doubly curved elliptical paraboloid made of a 76mm thin concrete shell, spanning 70m by 40m. This is equivalent to 1/13th of the thickness of an eggshell when compared to its relative span. The shell structure was at the forefront of engineering at the time and remains one of the largest and shallowest structures of its kind. Sixty years later, engineers were tasked with justifying the continued use of the roof while transforming the space below into the new London Museum. Using structural analysis software Oasys GSA and Oasys AdSec for detailed analysis, Arup concluded that a “do nothing” approach was best, maximising sustainability and positively impacting the environment.

As the building was set to become part of the Museum of London, the challenge was to repurpose it from its original use as a meat market. The design team needed to ensure the roof met modern performance standards to allow its continued use. Several analysis options were considered. It wasn’t enough to assume the structure’s age and condition would support new finishes similar to the existing ones, as this would mean accepting the existing risks. The engineers had to identify and quantify these risks. Additionally, the removal of the original finishes and the application of new ones had to be carefully planned to avoid impacting the sensitive structure. This required a detailed structural assessment, including material testing of the concrete and an investigative survey of the roof’s as-built shape. To revitalise the unique structure, the engineers used a modern reliability approach combined with an advanced digital workflow for detailed technical analysis of the roof.

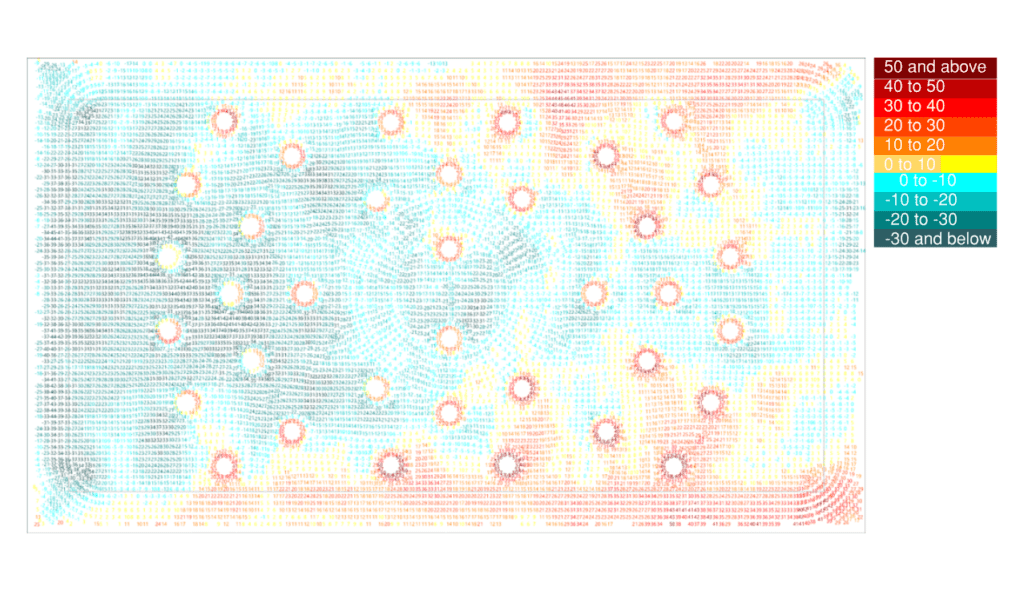

Point cloud surveys revealed that the roof’s thickness and shape deviated from the intended design. Additionally, material tests indicated that the concrete was both weaker and less stiff than expected. To assess the deviation of the as-built roof from the intended design, a comparison was conducted using Rhino and Grasshopper.

The roof exhibited significant asymmetrical deviations, including tilts and depressions, particularly on the left-hand side. These deviations impacted the roof’s structural performance, which relies on its intended shape. Survey data revealed that the roof’s thickness is less than specified in the design, with some areas being significantly thinner. Combined with reduced concrete strength and stiffness, these factors substantially affect the roof’s capacity, indicating that a ‘no worse than existing’ approach was inadequate.

Relative as-built deviation in mm (as surveyed) from design intent

How Oasys proved invaluable

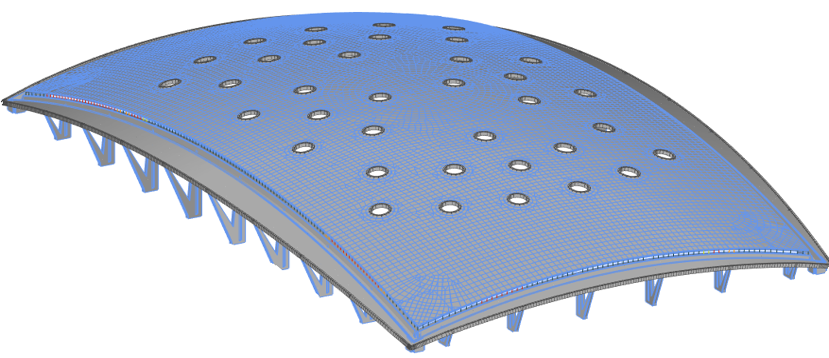

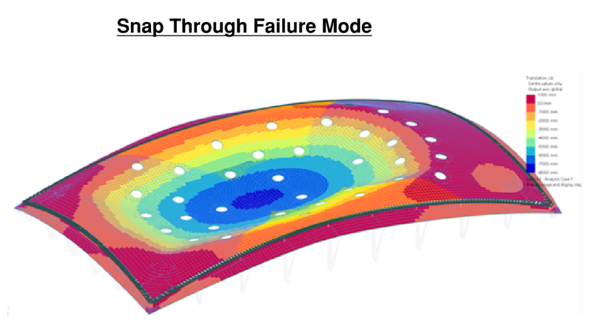

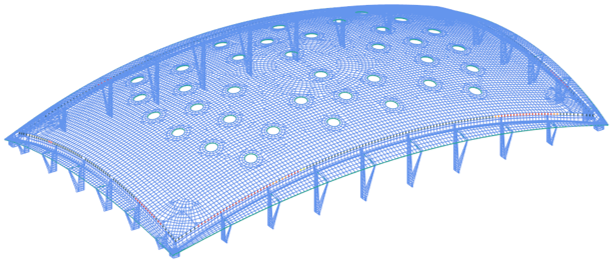

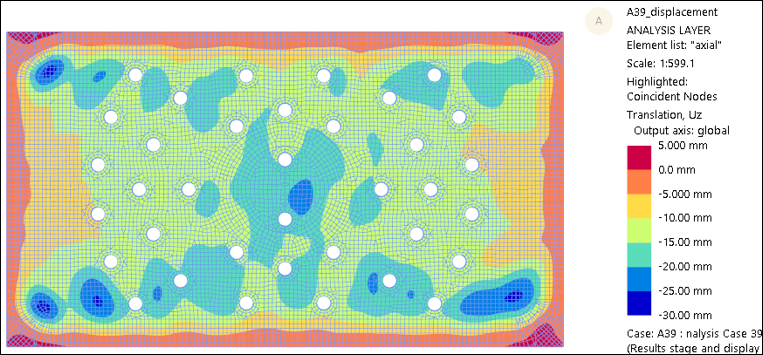

An analysis model was created in Oasys GSA using the survey results to reflect the as-built roof, including the point-cloud survey geometry, thickness, and material properties. The survey also allowed for accurate assessment of the screed load which were then applied in the detailed model. The thickness of the screed varied with the roof’s thickness, and loading was calculated accordingly. A detailed conventional analysis to modern Eurocode standards for new structures was carried out to assess the behaviour of the structure. The analysis was able to justify the structure for strength, but the verification for snap through buckling failed due to stiffness loss from cracking. This led to the design team adopting a new approach to justify the structure by determining minimum acceptable safety factors and developing an innovative analysis method to refine the structure’s assessed capacity.

Snap-through buckling failure in analysis model

Once the engineers determined the reliability index target, a deeper analysis was required to verify the global stability of the structure against snap through failure. The stiffness and shape of the roof is crucial for snap-through analysis and had to be accurately considered. The finite element analysis (FEA) model used the as-built shape from the point cloud survey to represent the geometry and thickness accurately. Since the structure has already experienced self-weight and post-tensioning effects, an adjusted ‘starting shape’ was found using an iterative Python workflow. This starting shape varies for each set of partial safety factors.

Accurately assessing stiffness loss due to cracking from applied loading was crucial. The analysis evaluated in-plane stiffness loss from tension, out-of-plane stiffness loss from bending, and the effect of twisting moments. Both in-plane and out-of-plane stiffnesses were assessed in two directions to represent the orthotropic behaviour of the reinforced concrete. When the stiffness in the roof’s shell elements changed, the cracking pattern from applied loading also changed, leading to new stiffness values for the FEA elements. A digital iterative workflow was created to find a compatible set of stiffnesses that represented the behaviour of the roof, updating them with each iteration. These iterations are numerical, not time-based, to find a solution with compatible stiffnesses across the roof.

The innovative method used in this project showed that the structure could meet modern performance demands without needing any strengthening work – the most sustainable outcome. This project redefines sustainable structural engineering by using comprehensive analysis to support a “do nothing” approach. This means the unique structure can continue its legacy without redevelopment, minimising environmental impact.

We’d like to thank Structural Engineers at Arup, Guusje Ubachs, Balduino Del Principe, Chris Noble and Richard Lawson for sharing this work with us.

“This project highlights the pivotal and unique role structural engineers play in breathing new life into existing structures. The iconic roof required extensive structural engineering analysis and thoughtful consideration to prove that maintaining the existing structure was the safest and best solution.” - “The project showcases how to “do nothing” through deep engineering analysis and insight, showing a profound understanding of structure and a vision for making a positive impact to our environment. The structural engineers undertook exceptional forensic structural analysis and demonstrate significant decision-making skills and technical knowledge.”