Software Used on this Project

Project Overview

This research project carried out by Durham University MEng student Arthur Chai, in collaboration with Arup and Oasys, addresses the complex challenge of foundation design and impact assessment in civil engineering. This area plays a crucial role in ensuring structural integrity, safety, and cost-effectiveness. Selecting the right foundation strategy requires careful consideration of factors such as soil properties, structural demands, and site constraints. This study explores how optimisation techniques can deliver an ideal load profile, improving efficiency and reliability whilst minimising impact on existing assets. The research draws inspiration from a recent real-world project delivered by Arup and uses cloud-based 2D geotechnical analysis software, Oasys Gofer.

Read the full research paper here.

How Oasys Proved Invaluable

The primary objective was to develop an efficient optimisation scheme for selecting the best loading profile for a site that had complex constraints due to the presence of shallow masonry Network Rail tunnels. Taking a traditional, manual approach to foundation optimisation would have been time-consuming due to having to perform many Finite Element Analyses (FEA) and manually selecting the model that best fits the criteria. This approach would also be difficult to re-use across projects.

To overcome this challenge, Arthur knew an automated approach would be most efficient. He reviewed relevant literature and optimisation techniques and used the Application Programming Interface (API) within Oasys Gofer to find the most effective foundation layout whilst minimising the stresses in the tunnel lining. The final aim was to be able to validate the optimisation scheme using real project data and provide practical recommendations for industry practitioners.

“Gofer being a cloud-based software enables the particularly useful API capabilities, something that was relatively uncommon among geotechnical FEA software during the project (and likely still is) and makes the workflow much more flexible.” – Arthur Chai

Automation tool

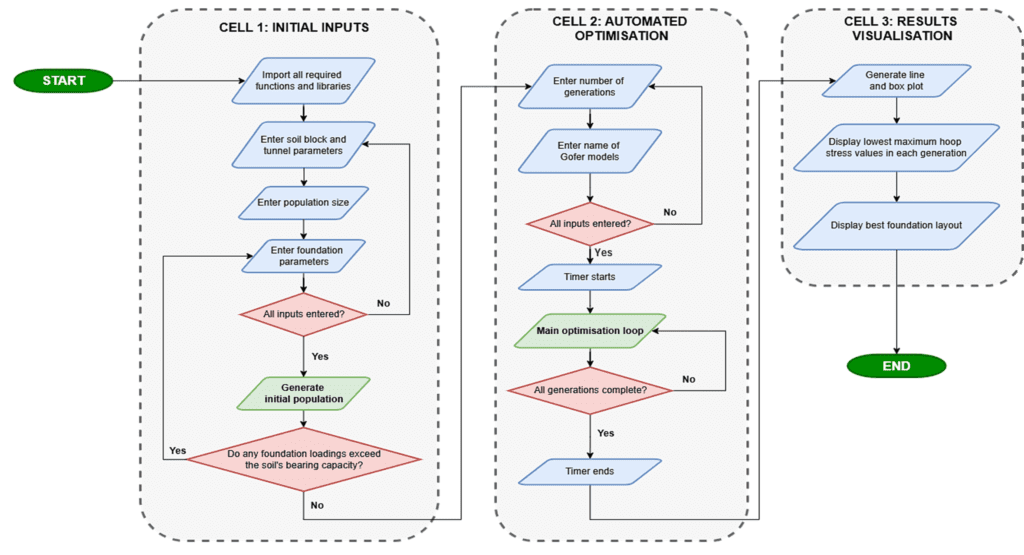

An automated tool in the form of a genetic algorithm optimiser with a wrapper function was developed in Python to optimise foundation layouts by minimising hoop stresses in the shallow underlying tunnels. With Gofer’s API integration, the FEA models were programmatically generated, analysed, and post-processed. Selected inputs from the user were required before the optimisation process runs from start to finish without user intervention. The tool adjusts for foundation loadings when they are moved and ensures they do not exceed bearing capacity of soil. It has grid sampling of initial foundation coordinates and a custom mutation function that perturbs the coordinates of the top-performing foundation sets from the previous generation. It automatically diagnoses correction of API errors and has a flexible framework allowing for future modifications.

A simplified high-level flowchart that displays the main structure of the developed optimiser. The processes are grouped according to their corresponding Jupyter Notebook cells.

Post-optimisation results

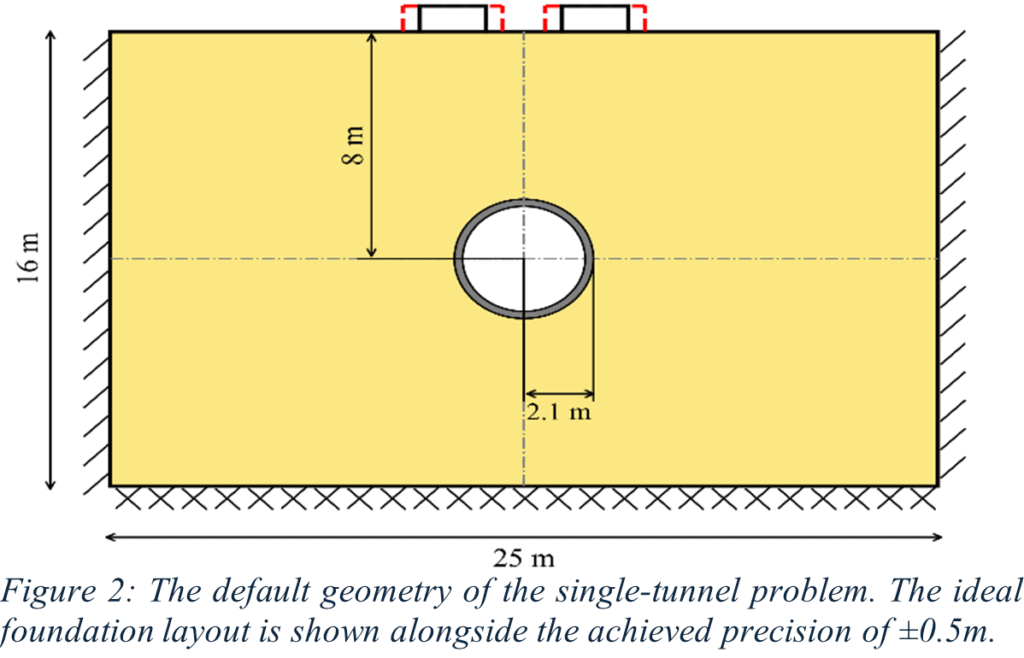

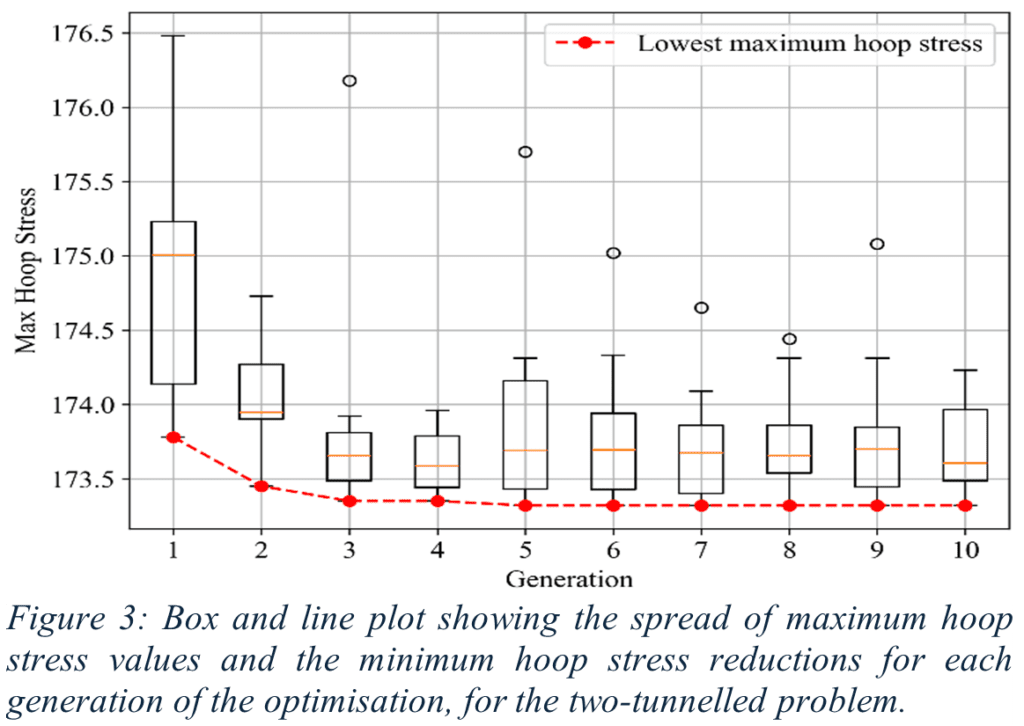

A single-tunnel problem was tested leading to successful reductions in maximum hoop stresses. These results were then evaluated against a minima graph showing the achievable maximum hoop stress values (~175.7-179kPa) with a minimum where the foundations are 2.15m each from the centre of the tunnel. An accuracy of ±0.1kPa for maximum hoop stress values was obtained, with a corresponding foundation location precision of ±0.5m. Each model took an average of 31.8 seconds to compute (53 minutes for 100 iterations). The tool was extended to cover a two-tunnel, three-foundation problem which was also successfully optimised, resulting in a reduction of the maximum hoop stress from just under 176.5kPa (overall worst) to 173.23kPa (overall best).

Summary and key learnings

The main highlight of this project is the development of an automated script which calls the Gofer API to build, analyse, and post-process models based on selected user inputs. This avoids the need for extensive manual setup and offers a simpler alternative to traditional geotechnical modelling workflows. The script was successfully used to minimise tunnel hoop stresses through adjustment of the foundation layouts.

It was found that bespoke adaptive meshing around the tunnel could be implemented to improve accuracy and precision further. Arthur concluded that multiple objective functions and built-in Gofer features can be added to the optimiser in the future to increase its functionality including soil stratification and hydraulic groundwater gradients.

We’d like to thank MEng student, Arthur Chai, and Professor Charles Augarde at Durham University for working together with us on this innovative project.

Explore the full research study and see how Oasys Gofer can help in your automation work – register your interest to speak to a member of the team.