Software Used on this Project

Project Overview

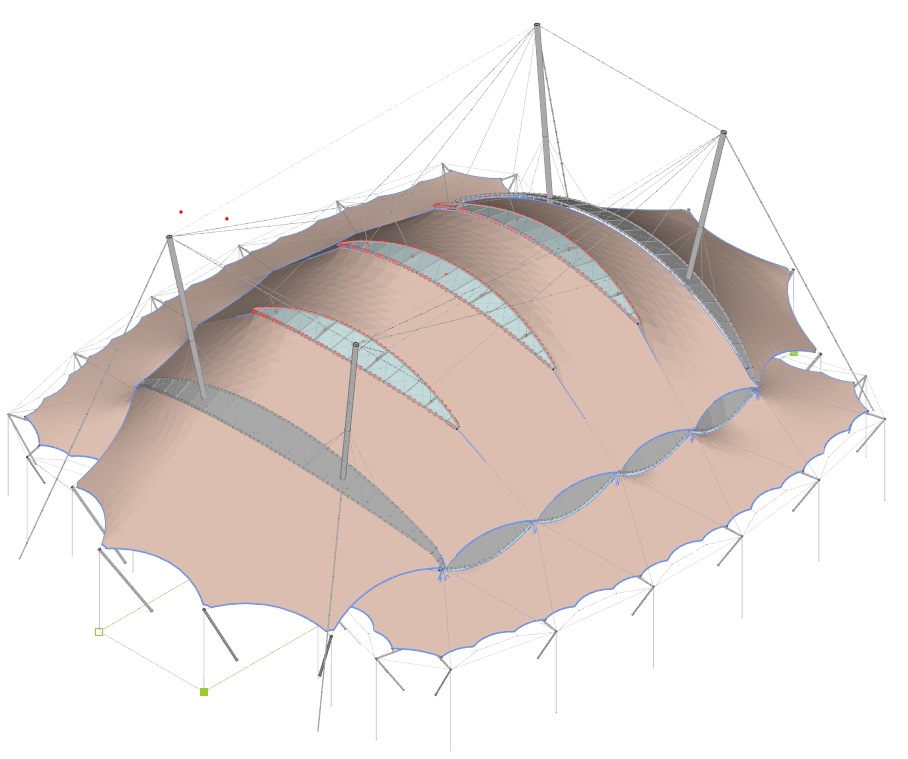

Completed in September 2025, Castle Meadow Campus at the University of Nottingham sits in the heart of Nottingham City Centre. Designed to strengthen connections between the city and the University, the campus serves as a collaborative hub for business, research, inspiration, and innovation. Arup was appointed to assess the structural behaviour of the Grade II-listed PTFE (polytetrafluoroethylene) tensile fabric roof, which needed replacing with a new PVC (Polyvinyl Chloride) alternative. Preserving the existing roof’s form was a key requirement, so the analysis models had to accurately reflect the current geometry rather than generate a new one for the PVC fabric. To achieve this, Oasys GSA form-finding analysis models (powered by GsRelax) were integrated with other essential modelling tools, Revit, and Speckle.

Images credit: GF Tomlinson

How Oasys Proved Invaluable

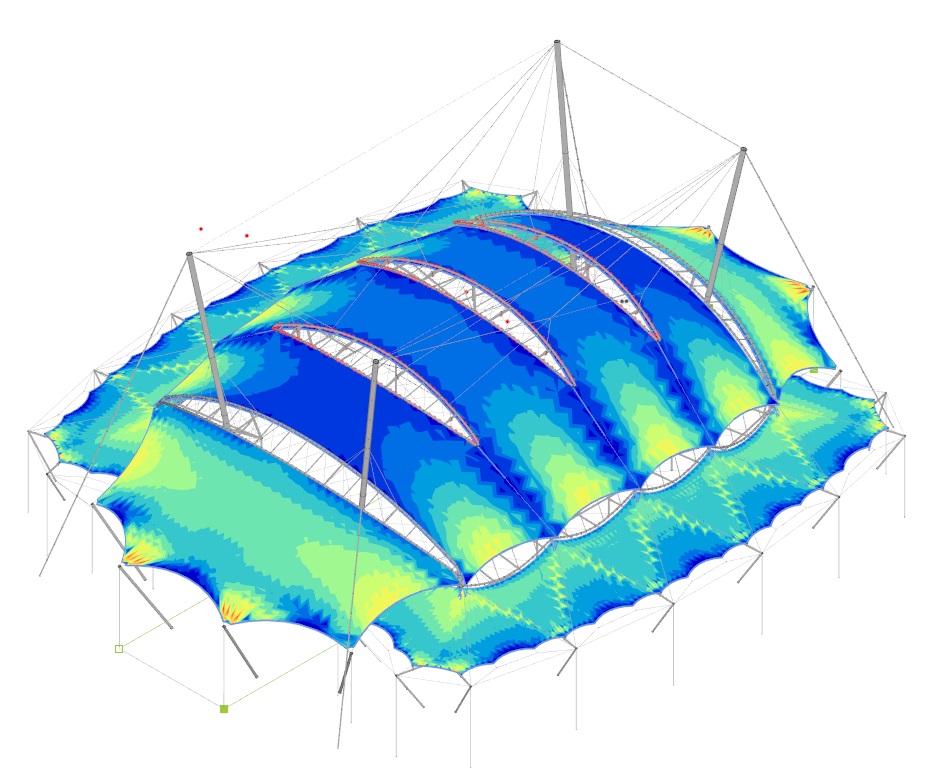

GsRelax was used to analyse the behaviour of the Grade II-listed PTFE tensile fabric roof. The project involved integrating Oasys GSA analysis models with other modelling tools. A Speckle connection to Revit enabled the import of frame geometry, captured via LiDAR scan, into GSA. GsRelax and the staged analysis function allowed the team to assess how the structure behaved during the complex deconstruction and reconstruction sequence.

Using GSA, the engineers imported geometry from a Revit model of the steel supporting structure, created from a LiDAR point cloud, along with a node map from the fabric designer’s proprietary design software. This enabled them to use GsRelax with a staged analysis to analyse the structure at key points in the reconstruction sequence.

The reconstruction sequence involved jacking the existing structure to transfer load to temporary straps and lifting beams, followed by destressing the structure as the primary roof trusses were lowered to allow removal of the existing fabric. GsRelax, combined with staged analysis, enabled engineers to monitor structural stresses throughout jacking, destressing, and replacement sequence. This revealed how load paths shifted during the works and highlighted the need for props at the nodes of the side oculi trusses once the central trusses were lowered. The model was subsequently used to develop requirements for the design of these temporary works.

Summary and Key Findings

Carrying out staged analysis enabled the development of a successful replacement sequence, helping identify the need for temporary propping.

The engineers imported input data from multiple sources (Revit, Speckle, and .gwa files) to create the analysis model. The process was highly intuitive, allowing the team to construct a complex model within just a few hours. Staged analysis was critical in understanding how the structure responded during deconstruction and fabric replacement sequence. The engineers were able easily define the different material properties of the existing PTFE and the new PVC fabric to assess the impact of the change.

“Overall, this project would not have been possible without the use of GSA.” – Senior Structural Engineer at Arup, Stuart McNash.

We’d like to thank Stuart for sharing this information with us.

Head to the product page to learn more about GSA’s flexibility or register your interest to talk to a member of the team.