Project Overview

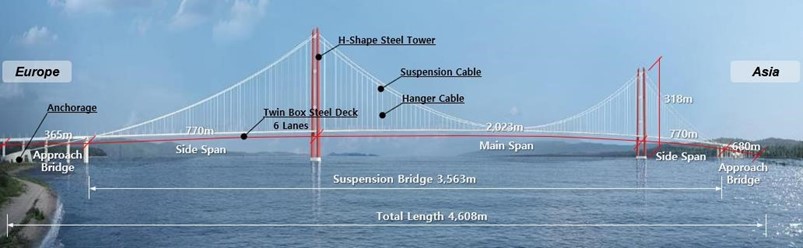

The 1915 Çanakkale Bridge is a long-span suspension bridge crossing over the Dardanelles straits in Turkey. In line with UN SDG 11, the bridge makes the connectivity between local communities faster and safer, while reducing fuel emissions and reducing the need for ferries. Employed by the Contractor joint venture DLSY, Arup provided design verification for both permanent and temporary structures using Oasys GSA, Oasys AdSec and the associated Grasshopper API.

1915 Çanakkale Bridge general characteristics

How Oasys proved invaluable

Arup was tasked with the technical review of the design packages issued by the designer COWI. Following review, the engineers carried out the calculations to verify the conformity of the design packages with the project Design Basis. To do this, detailed verification tools were developed using Oasys AdSec, Oasys GSA, and parametric modelling using Grasshopper and its Oasys plugins.

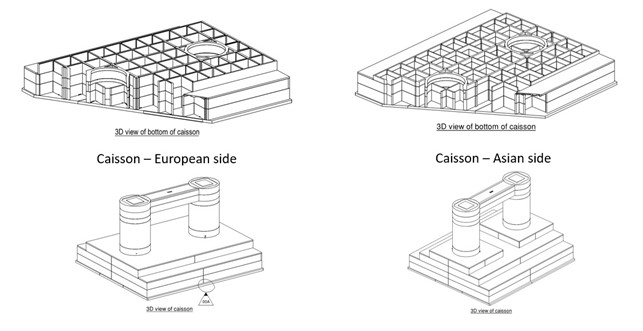

The bridge towers are supported by concrete caissons, resting at the bottom of the sea on their 80mx70m base slab. The caissons were erected in a dry dock, then floated out and sunk to their final position. The caissons are hollow and made of an array of slabs and walls.

Tower foundation caissons float-out

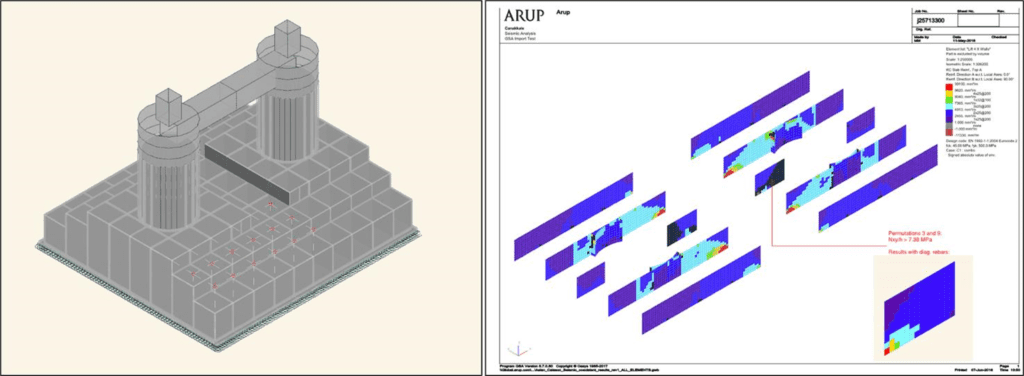

Arup identified several errors in the rebar design of the caissons. Local models of the caissons were generated in GSA using 2D shell elements, allowing to model the proportions of the walls and slabs, identify load paths, and assess in-plane effects. The general actions were applied at the top of the caissons and were extracted from the Global Analysis Model (GAM) developed by a sub-consultant.

Isometric overview of the foundation caissons

The models enabled the engineers to assess the effect of actions in each wall and slab of the caissons. A postprocessing tool implemented in GSA, called RC Slab Design, was used to determine the section area of reinforcement requirements based on the internal stresses in 2D elements. Comparisons were drawn between designs reinforcement drawings and the reinforcement requirements extracted from the model.

Overview of the caissons local GSA model (left), and result output from RC Slab Design (right)

RC Slab Design can express ‘concrete failures’ by showing the elements in a black colour, meaning the postprocessor is unable to determine a section area of reinforcement that would make the element resist the loads. Typically, the concrete failures exposed by RC Slab Design are due to an excess of either compression or in-plane shear. From the model outputs, the engineers identified that the compressive stresses in these areas were far below the concrete strength. By process of elimination, they concluded that in-plane shear was the issue.

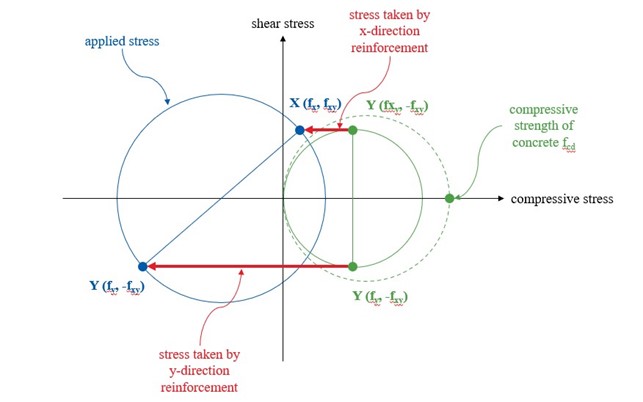

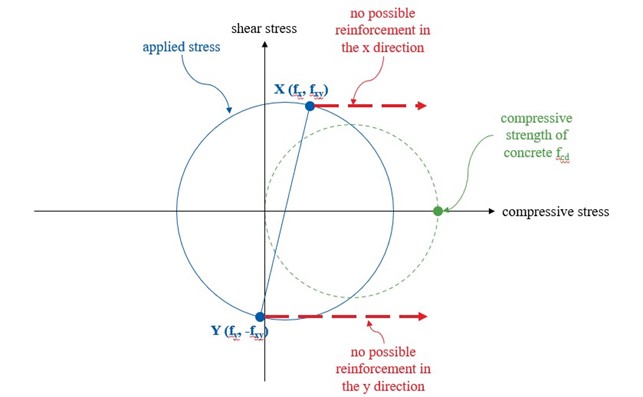

To verify the result output of RC Slab Design, they drew Mohr circles of the failing elements to identify their stress state, using the stress outputs from GSA. The Mohr circle representation for an element that would pass an in-plane shear check is shown below.

Mohr circles for an element without in-plane shear failure

Similarly, the Mohr circle representation of an element undergoing in-plane shear failure would look like is shown below. No amount of reinforcement in orthogonal directions would prevent the failure.

Mohr circles for an element with in-plane shear failure

The engineers determined that three options can improve the resistance of concrete to in-plane shear: Increase the grade of concrete, increase the wall thickness or align the reinforcement with the direction of the shear force. It was agreed to align reinforcement to the principal directions of stresses, leading to the local addition of diagonal reinforcement in the walls.

The wall areas were located and measured where diagonal reinforcement was needed, before modifying the GSA verification models to implement the use of diagonal reinforcement. Further analyses were run to determine the necessary reinforcement in these specific directions.

Çanakkale Bridge site visit – Richard Hornby (left), Jonas Winterhalter (right)

We’d like to thank Jonas Winterhalter, Bridge Engineer at Arup, for sharing this work with us.

For more information about Oasys GSA, head to the product page. Want to talk to the team about the Grasshopper plugin? Register your interest today.