Software Used on this Project

Project Overview

UCLH aims to provide a patient-focused therapeutic environment for cancer patients, their families and carers, using best-practice models from around the world. The building contains accommodation for general cancer care, private patient cancer care and clinical facilities as well office accommodation.

The development is in the London Borough of Camden, bounded by Mortimer Market to the west, University Street to the north, Huntley Street to the east, and adjacent to an existing building, The Rayne Institute to the North West.

This case study presents the process of retaining wall and pile design adjacent to the Rayne Institute piles.

How Oasys proved invaluable

Geotechnical Constraints

For the basement construction, the section of retaining wall running alongside the Rayne Institute had several architecturally imposed restrictions which required a different approach to the rest of the retaining wall.

Due to requirements to locate a service lift at this edge of the building there were tight space restrictions that impacted the wall thickness and the wall offset from the adjacent Rayne Institute.

Overview of the Geotechnical Solution near the Rayne Institute

Arup proposed the construction of a 600mm diameter hard-soft bored secant pile wall with male piles at 750mm diameter centres and with a structural skin wall to provide long term water tightness. In addition, the reinforcement requirements for this section of wall needed to be assessed in light of the small pile diameter.

The smaller pile diameter of 600mm in this area required the wall to be temporarily propped at two levels, where a steel waling beam with associated propping was adopted for the intermediate level. To avoid undermining the basement of the adjacent Rayne institute building it was proposed that the capping beam over this section of wall be raised above the new lower ground floor basement level (forming an upstand in the final condition).

The effect on the Rayne Institute piles needed to be carefully analysed and movements due to excavation of the adjacent basement needed to be carefully controlled. This was further complicated by the fact that the Rayne Institute piles were not fully reinforced over their length.

Analysis

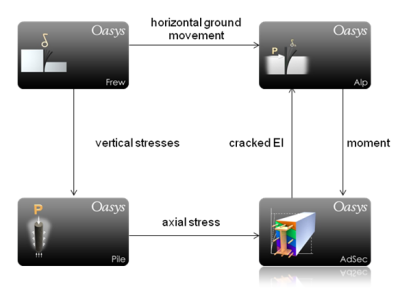

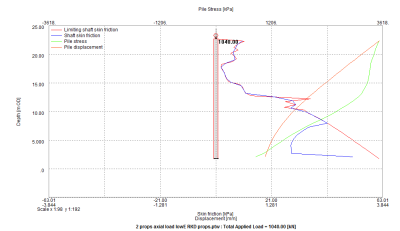

The impact of the movements on the Rayne Institute piles due to excavation in front of the secant pile wall were assessed in an iterative manner using Oasys Frew, Alp, Pilset (now incorporated into Pile 19.1) and AdSec.

A summary of this calculation is shown below:

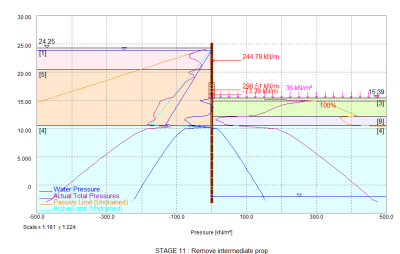

Oasys Frew was used to calculate the horizontal ground movements caused by the construction sequence of the UCLH retaining wall.

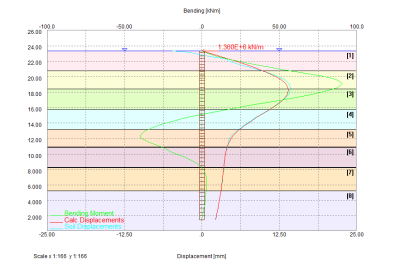

The horizontal ground movements from Oasys Frew at different construction stages were applied to Oasys Alp to assess the bending moments induced in the 600mm piles.

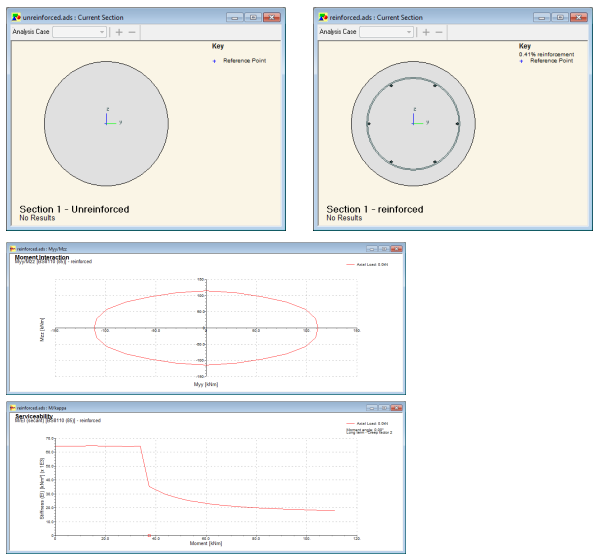

The bending moments from Oasys Alp were used to check the capacity of the reinforced and unreinforced sections of the piles in Oasys AdSec. In turn the Stiffnesses (EI values) from AdSec were fed back to Alp in an iterative process.

For the unreinforced piles, axial compression caused by axial loading needed to be considered to allow the bending moment capacity to be assessed. The axial loading that was applied in Oasys AdSec was calculated using Oasys Pilset (now incorporated into Pile 19.1), and based on the loads applied from the building. Pilset also calculated the settlements of the piles due to stress changes in the surrounding soil caused by secant pile wall movements. The stress changes in the soil were extracted from FREW and applied in Pilset.

The Arup geotechnical engineers were able to use this iterative approach due to the compatibility between the programs and the ability within the programs to quickly make changes to produce results.